Age Hardening Also known as precipitation hardening. A hardening method for certain alloys which are held at an elevated temperature for between 1 hour and several hours, causing a precipitation of a constituent from a supersaturated solution. Examples are beryllium copper and 17-7 stainless steel.

Allow for Set Spring is supplied longer than specified to compensate for length loss when fully compressed in assembly by customer.

Austempering A hardening method where steel is quenched from above the transformation point to a temperature slightly above the upper limit of martinsite formation and held there until austenite is transformed to bainite.

Baking Heating of electroplated springs to remove hydrogen and relieve hydrogen embrittlement.

Blueing Heating until forming a thin blue film of oxide on ferrous alloys.

Buckling Bowing or lateral deflection of compression springs when compressed, related to the slenderness ratio.

Closed Ends Compression spring ends with pitch reduced on the last coil so that end is squared up and tip touches last coil.

Closed and Ground Ends Same as with closed ends, except that the end is ground to provide a flat end.

Closed Wound Coiled with all coils in contact with each other.

Creep See relaxation.

Decarburization Loss of carbon from the surface of steel during a high temperature process.

Deflection Motion of spring ends or arms under the application of an external load.

Ductility Plastic deformation of a material before fracture.

Elastic Limit Maximum stress to which a material may be subjected without permanent set.

Endurance Limit Maximum stress at which a material will operate for a stated number of cycles without failure.

Fatigue Life The life of a spring in number of cycles when it is loaded numerous times.

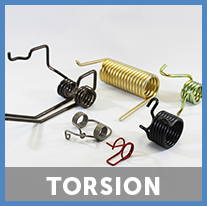

Free Angle Angle between the arms of a torsion spring when the spring is not loaded.

Free Length The overall length of a spring when unloaded.

Goodman Diagram Derived from S-N curves and used to predict cycle life.

Hand The direction in which a spring is coiled. Right hand wound would fit over a right hand thread and left hand would fit on a left hand thread.

Heat Setting or Hot pressing Fixturing a spring at elevated temperature during manufacturing in order to improve stress relaxation during service.

Helical Springs Springs coiled in a helical form such as compression, extension and torsion springs.

Hydrogen Embrittlement Brittleness in a material caused by retained hydrogen that has been absorbed during pickling or electroplating.

Hysteresis The difference in load at a particular point between loading and unloading. Caused by friction, and is most evident when the coils rub on the mating part, such as a torsion spring working over a pin.

Initial Tension The force that keeps the coils of an extension spring closed and which must be overcome before the coils start to open.

Load The force applied to a spring that causes a deflection .

Loops Coil-like wire shapes at the end of extension springs that provide for attachment and force application.

Mean Coil Diameter Outside spring diameter (O.D.) minus one wire diameter.

Modulus of Elasticity in Shear or Torsion (Modulus of rigidity, G) Coefficient of stiffness for extension and compression springs.

Modulus of Elasticity in Tension or Bending (Young's modulus, E)Coefficient of stiffness used for torsion and flat springs.

Moment See Torque.

Natural Frequency The speed at which a spring will inherently vibrate.

Open Ends, Not Ground End of a compression spring with a constant pitch for each coil.

Open and Ground Ends constant pitch of the coils but ends ground.

Passivating Acid treatment of stainless steel to remove contaminates and to restore the oxide film thereby improving its corrosion resistance.

Patenting A process of heating carbon steel above its critical temperature and then cooling slowly, resulting in a fine pearlitic microstructure with good ductility and conducive to drawing.

Permanent Set The difference between the original free length of a spring and its length after being deflected to a certain height and released.

Pitch The distance from center to center of the wire in adjacent active coils (recommended practice is to specify number of active coils rather than pitch).

Precipitation hardening See Age Hardening.

Preset Removal of set by deflecting a spring to a high stress condition and releasing.

Rate Change of load per unit deflection.

Relaxation Plastic deformation of a material over a period of time, usually at elevated temperatures.

Remove Set See preset.

Residual Stress Stresses induced by preset, shot peening, cold working, forming etc. Residual stresses may sometimes be beneficial as in the case of shot peening and preset.

Scragging Pressing to solid to remove set. (see Preset)

Set Length change cased by deflection beyond the materials elastic limit.

Shot Peen Bombarding the wire surface with small steel shot to induce compressive stresses and thereby improve fatigue life.

Slenderness Ratio Ratio of spring length to mean coil diameter. The major factor in determining if a spring will buckle.

Solid Height Height of a compression spring when under sufficient load to bring all the coils into contact with adjacent coils.

Spring Index Ratio of the mean coil diameter to wire diameter.

Squared and Ground Ends See Closed and Ground Ends.

Squared Ends See Closed Ends.

Squareness of Ends Angular deviation from vertical of a compression spring when standing upright.

Squareness Under Load Same as Squareness of Ends, except with the spring under load.

Stress Relieve A low-temperature heat treatment used to relieve residual stresses.

Tensile Strength The maximum tensile stress that a material is able to take. It is equal to the maximum force required to break the material divided by the original cross-sectional area of the material.

Torque The product of the distance from a torsion spring's axis to the point where a load is applied and the component of force perpendicular to that lever arm. Torque is usually expressed in inch-pounds or in foot-pounds.

Total Number of Coils Number of active coils plus the inactive coils forming the ends.

Wahl factor A stress correction factor used to account for the effects of curvature and shear.

Yield strength The stress at which a material begins to experience "plastic deformation" or permanent deformation. Usually defined as the point at which .2% permanent elongation is experienced by the material.